�� Check the timing of the end of blowing of the main nozzle

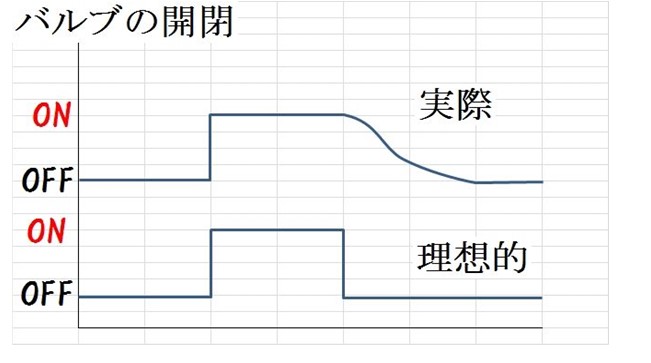

About the actual behavior of the air valve

Above actually��Below ideal

When the air valve closes, the air does not completely come out at the timing

when the electric signal is turned off, but it is as shown in the above figure.

When the air valve opens, the air pressure helps and the air comes out ideally,

but when the air valve closes, the air pressure interferes and it tends to be a little delayed.

If air is still coming out of the main nozzle when the weft is fully stretched,

stress will be applied to the weft and the weft may break.

Standard timing

���ѥ���Spun yarn���ե�����Ȼ��Filament yarn

���ѥ���Spun yarn���ե�����Ȼ��Filament yarn

The standard is set as shown in the above figure, but it varies depending on the thread count and reaching angle.

If there are many weft breakage detections in WF2, try advancing the end timing.