�� Check the injection timing of the sub nozzle

Check using the above sheet.

The new loom(after JAT600) sets the timing automatically.

However, there are times when the automatic settings are out of order, so there are times when I check.

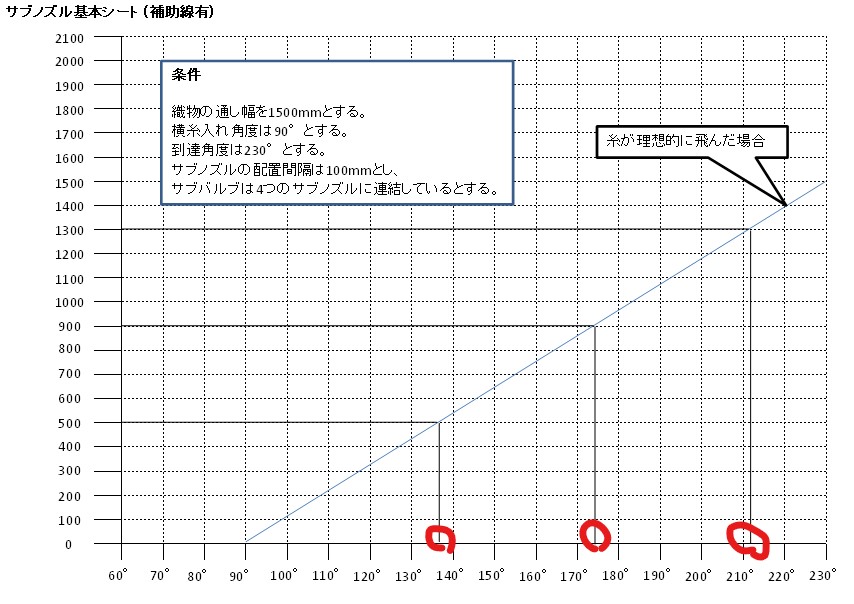

Setting Example

Point �� Open earlier than the arrival timing

conditions

conditions

Reed width is 1500mm

The probability that the weft will enter is 90 ��.

The reaching angle is 230 ��.

Sub-nozzle placement interval is 100 mm

Sub-valve is connected to 4 sub-nozzles

The optimum setting for this condition is as follows.

The injection start timing of the sub valve 1 starts from 90 �� or less.

The injection start timing of the sub valve 2 starts from 135 �� or less.

The injection start timing of the sub valve 3 starts from 175 �� or less.

The injection start timing of the sub valve 4 starts from 210 �� or less.

The sub-nozzle needs to blow air before the thread reaches it.

The reason is that if air is discharged from the sub-nozzle after the yarn arrives,

the yarn posture may be lost and a large loop may occur.

Even if the signal reaches the valve,

the valve cannot be opened and closed instantly, so it is better to set it a little earlier.

Point�� Open the valve early because the arrival angle of the thread varies

Since the spun yarn is not uniform, the yarn does not fly in the same way.

Therefore, the reaching angle varies.