�� When the cause is poor opening of the warp

��If the fluffing is insufficient due to poor sizing, or if there is no glue, the warp threads may stick to each other due to the fluff, resulting in poor opening.

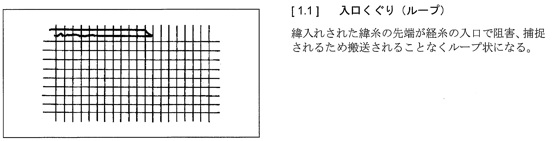

Especially if the tension at the start side edge of the woven fabric is loose, it will look like the following video.0:28��0:29

https://youtu.be/or6E2JFsEvY

��If the warp tension is low, the opening tends to be poor.

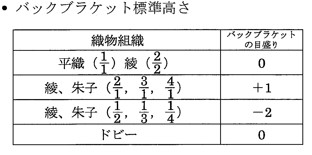

��If the back height is not appropriate, the difference in tension between the upper and lower warp threads at the time of opening will result in poor opening.

��When the relax amount and relax time are not appropriate

��When the relax amount and relax time are not appropriate

If the relax amount is not appropriate, the thread may be stressed and the thread may stretch, resulting in poor opening.

If the relax time is not appropriate, the thread will be stretched and the opening will be poor.

��When the cross timing for each frame is uniform

Since the warp threads are aligned in a row, it is easy for the opening to be defective.