Optimal height

The frame height of the loom is set to the standard height set by the manufacturer before delivery.

However, depending on the woven fabric structure, it may be more convenient for weaving to change the frame height.

As an example, let’s take the case of weaving a 3/1 twill.

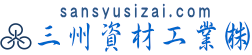

When the frames cross, there is no frame to pull down as shown above, so the front weave is pulled up.

When the frames cross, there is no frame to pull down as shown above, so the front weave is pulled up.

If the front weave is pulled upwards, the following problems may occur.

�� Reed’s jaw striking defect

�� The entry angle of the weft is restricted

Therefore, in some cases, it is more efficient to weave by changing the frame height according to the woven fabric structure.

As a guide (the standard frame height is often plain weave)

�� In the case of 3/1, lower ��3-1 = 2�� 2 mm.

�� In the case of 2/1, lower ��2-1 = 1�� 1 mm.

�� In the case of 1/3, raise ��3-1 = 2�� 2 mm.

Due to the difference in the weaving structure, the front of the weave moves as shown in the above figure,

so the jaw striking defect and the sub-nozzle muscle defect occur depending on the frame height.