��-1 Check the height of the sub nozzle

The height of the sub-nozzle is related to the thread carrying force,

but it is not necessary to adjust all to a uniform height.

If the number of sub-nozzles, which are higher or lower than the standard, is unevenly arranged, it may cause a problem of carrying force.

��-2 Check the angle of the sub nozzle

The angle of the sub-nozzle can be an issue.

Especially if you are using a type of sub-nozzle that is not a reverse taper type,

you need to switch all sub-nozzles to the optimum angle every time the fabric changes.

This is because the injection direction of the sub-nozzle changes depending on the air pressure.

Sub-nozzle form������Sub-nozzle form��

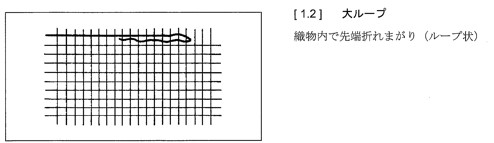

If the direction of the air injection from the sub-nozzle is too directed toward the reed,

the thread posture will be easily disturbed and it may stop in a large loop.