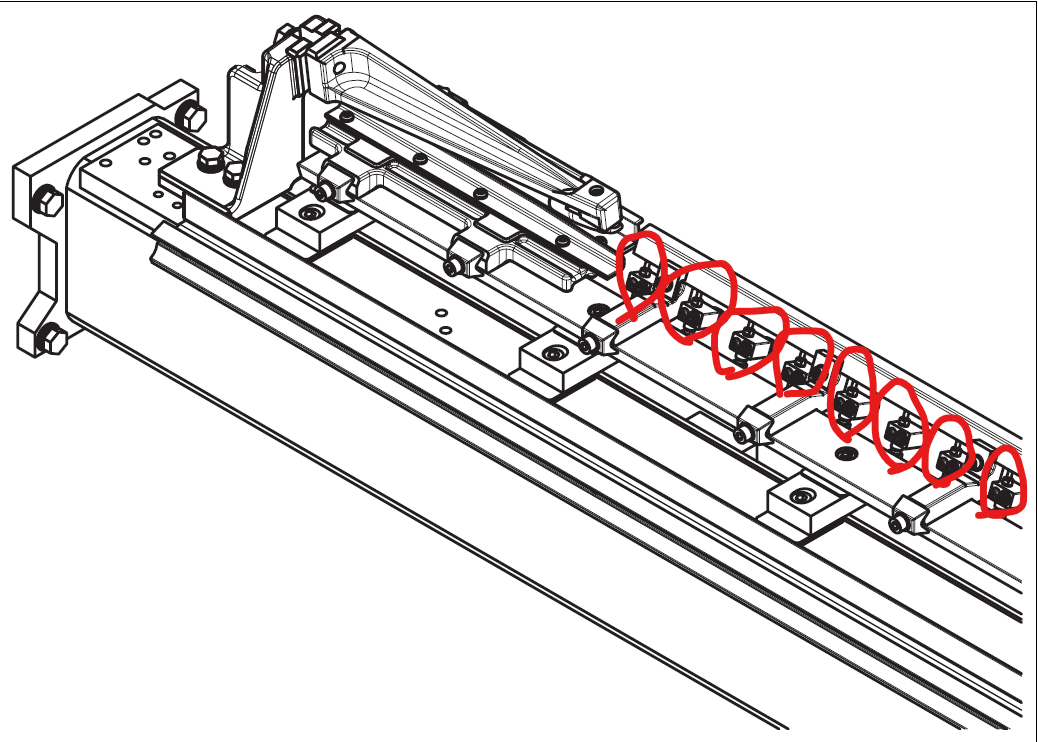

Many sub-nozzle form

Many sub-nozzle form

sub-nozzle form is has changed significantly compared to the past and the present.

Let’s look back on the sub nozzle form change history!

①Single hole sub-nozzle

Sub-nozzle in the early days of air jet loom(AJL).(1970~1990?)

It had just one hole.

②Double hole sub-nozzle

It developed about 30 years ago.(1990~2000?)

It is used in the model of JAT600 (Toyota Industries.)

The direction of sub-nozzle air jet has been improved.

However, the air jet direction is significantly different between low pressure and high pressure.

③Reverse taper sub-nozzle

It developed about 20 years ago.(2000~2005?)

It is used in the model of JAT710 (Toyota Industries.)

The sub-nozzle air jet directionality is further improved as compared with the Double-hole nozzle.

Although the sub-nozzle air jet direction changes at low pressure (2k or less),

If the pressure is higher than that, sub-nozzle air jet direction can be blown in a uniform direction.

④New Reverse taper sub-nozzle

It developed about 5~7 years ago.(2013~2015?)

It is used in the model of JAT810 (Toyota Industries.)

Improved the air jet direction at low pressure, which was a drawback of the reverse taper sub-nozzle.

Pressure and directional behavior are different for each nozzle

As described above, depending on the type of sub-nozzle, the air jet direction of the sub-nozzle changes depending on the pressure.

Therefore, it is possible that this sub-nozzle characteristic is related to the fact that the yarn does not fly well when the fabric is changed.

Conversely, if the latest sub-nozzle is used, it means that you will be freed from detailed adjustment work.